self-reinforced Polyphenylene (SRP)

Properties and Applications

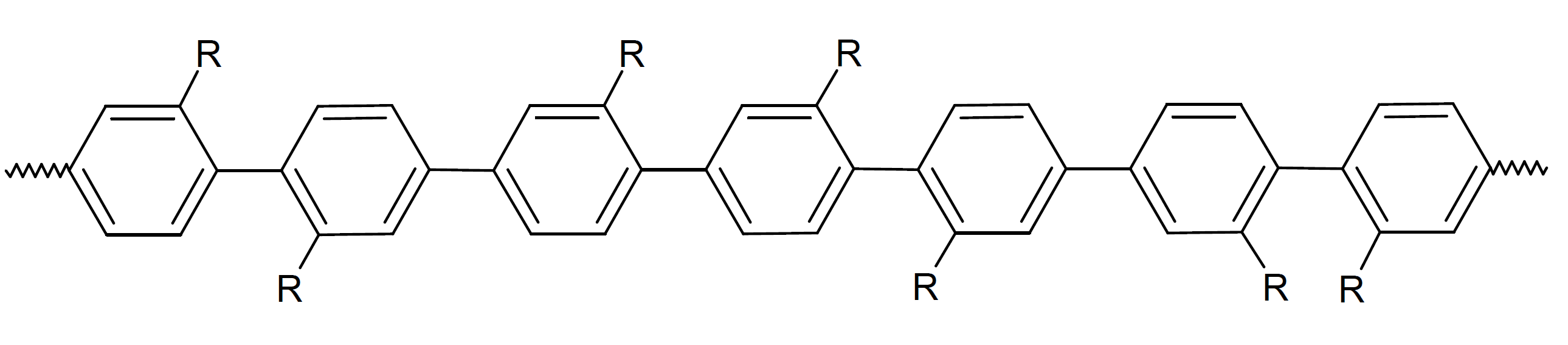

Self-reinforced polyphenylene (SRP, PPP) is one of the stiffest and strongest melt-processable engineering thermo-plastics on the market.1 For engineering applications, para-phenylene is typically copolymerized with other monomers and/or the phenyl rings have substituents chosen from a wide range of organic groups. Both greatly improves processability so that the resins can be compression molded or extruded into complex part geometries.

Due to its inherent rigid rod-like structure, it possesses outstanding mechanical properties over a wide temperature range even without fiber reinforcement. In addition, it possesses exceptional abrasion and solvent resistance, outstanding thermal-oxidative stability, and inherent flame resistance. It also exhibits unusual electronic and optical properties and can be processed into crystalline thin films, for example by vacuum deposition, which become electrically conducting when doped. Its exceptional mechanical, chemical, thermal and electrical properties make SRP an excellent choice for many very demanding applications including semiconductor components, high performance bushings, bearings and aircraft substructures. Due to its high specific strength, SRP is an excellent candidate for light-weight high-performance applications.2

Manufacturers & Distributors

Brand Names

1The tensile strength of PrimoSpire SRP (Solvay TDS) is comparable to that of PEEK.

2 The specific strength (force per unit area at failure) of PrimoSpire PR-250 exceeds those of some aluminum and stainless steel alloys.