Polyphenylene Oxide (PPO)

Properties and Applications

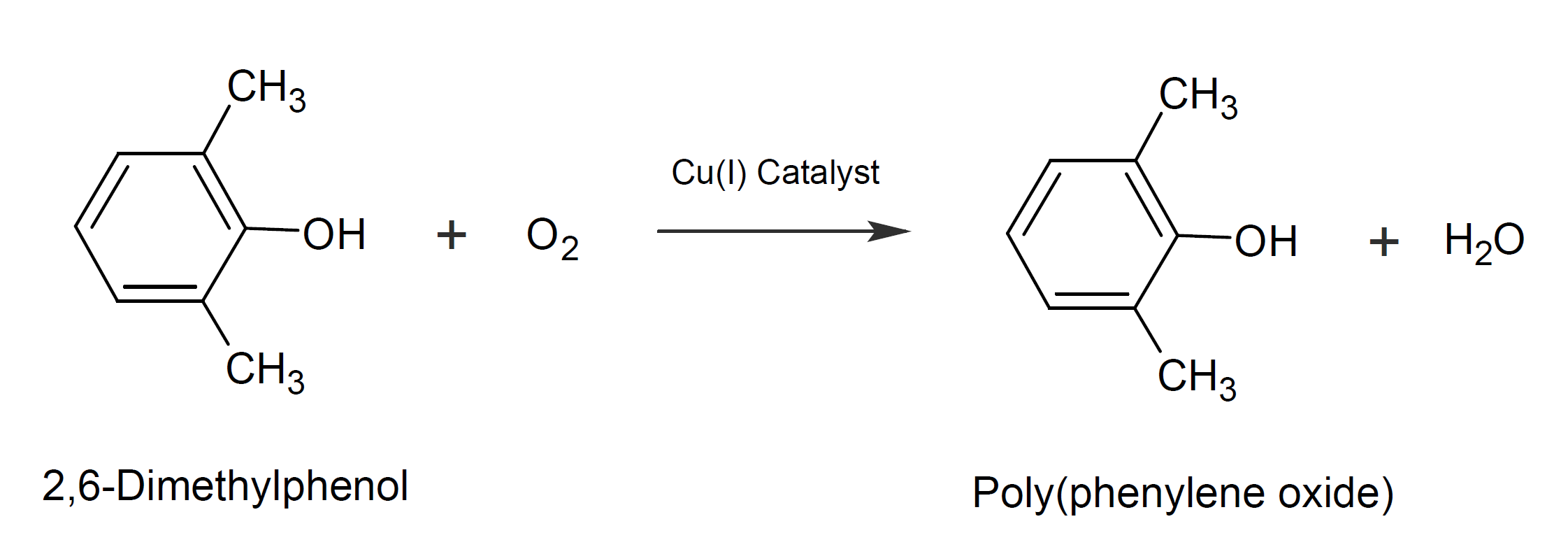

Polyphenylene oxide1 (PPO), aiso known as polyphenyl ether (PPE), is a high performance amorphous engineering thermoplastic. It is synthesized by oxidative coupling reaction between 2,6-dimethylphenol (DMP) and oxygen. This reaction proceeds under mild conditions to produce only water as the by-product.2

PPO has high tensile and impact strength and is resistant to many chemicals including steam and hot water as well as mineral and organic acids but is sensitive to stress cracking.

Despite its many attractive properties, PPO and its derivatives have found only limitted commercial use. The susceptibility of PPO to themal oxidation in relation to its high glass transition temperature poses a significant problem for melt processing. For this reason, commercial resins are often blended with high-impact polystyrene (HIPS) with which it is fully compatible or with polyamide (PA). Some filled grades of PPO find uses in the automotive and electronic industry. Examples include pump parts, fan impellors, catalyst supports, plugs, insulators and household articles.

Commercial grades of (modified) polyphenylene ethers are available from Ensinger Ltd. ( (Tecanyl), and SABIC ( Noryl™). Besides pure PPO, also blends of PPO and polystyrene and polyolefins (PP) are available that offer a wide range of flexibility, toughness, and flame retardancy. The resins are available in injection-moldable, extrudable and foamable grades.