Polypropylene carbonate (PPC)

and other Aliphatic Carbonates

Properties and Applications

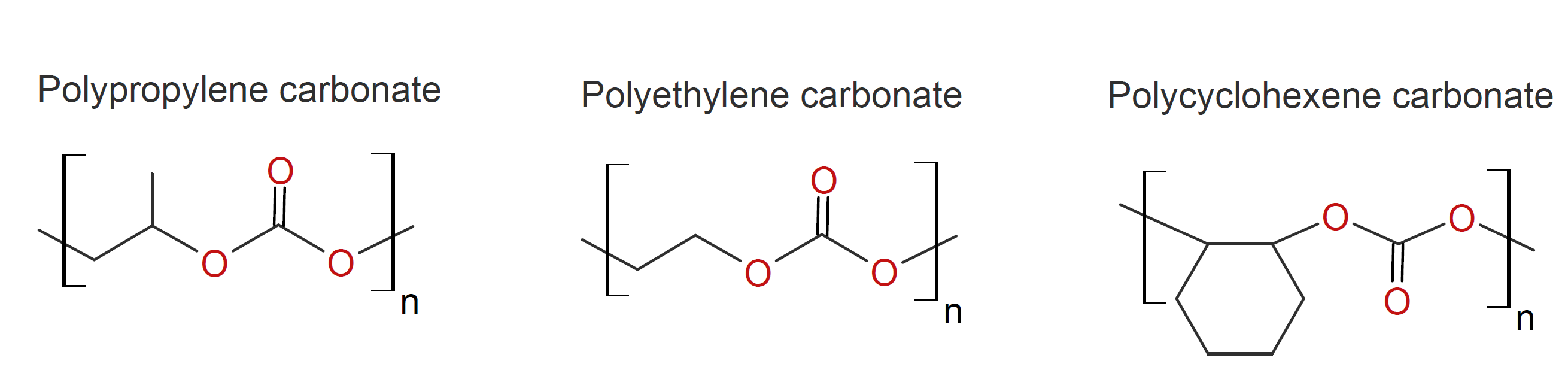

Polypropylene carbonate (PPC) is a fully biodegradable and environment-friendly thermoplastic synthesized from carbon dioxide and propylene oxide. It is fully amorphous and has a rather low glass transition temperature of about 40 °C, and thus is rather soft at room temperature. Two other polycarbonates that have found some commercial uses are polyethylene carbonate (PEC), and polycyclohexene carbonate.

Aliphatic polycarbonate diols (PCDs) can be used as a chain extenders for elastomers such as thermoplastic urethanes. When copolymerized with isocyantes, they improve their flexibility, toughness, and adhesive strength. They also provide excellent chemical & hydrolytic stability as well as thermal and abrasion resistance. They are generally more expensive than polyether and polyester diols but have superior aging properties. Thus, this class of polyols is mainly used for high performance polyurethane elastomers operating in harsh environments. Aliphatic polycarbonates can also be used as a toughening agents in thermoset resins, as a sacrificial binders in ceramic compositions, and in biodegradable plastics such as PPC/starch blends.

Manufacturers & Distributors

Companies |

Brands |