Polymethylpentene (PMP)

Properties and Applications

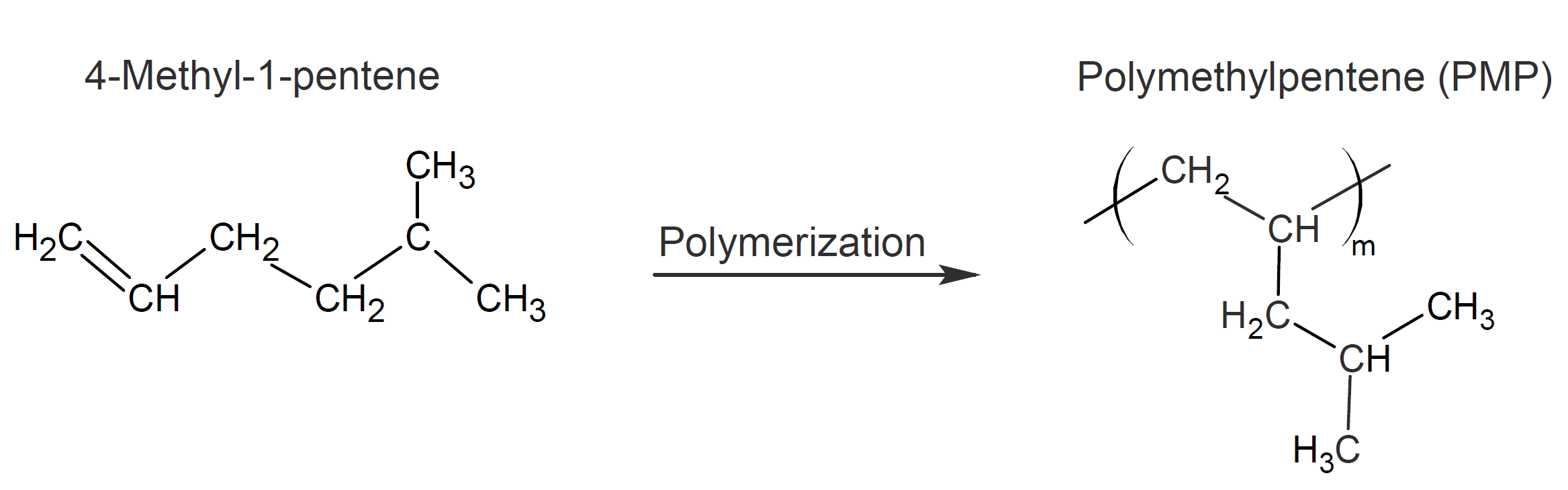

Polymethylpentene (PMP) is a highly transparent and extremely low density olefinic commodity thermoplastic. Unfilled grades have a specific gravity of only about 0.83 g/cm3 making it one of the lightest thermoplastics. It is manufactured by polymerization of 4-methylpentene-1 using Ziegler-Natta catalysts.

The properties of polymethylpentene are very similar to those of other olefins including excellent electrical properties, good chemical resistance, extremely low water absorption rate, and high hydrolysis resistance. In addition, it is of high transparency with light transmission values of more than 90 percent which is equivalent to glass and acrylics. PMP also has a relatively high melting point of approximately 230°C (250°F). To further improve its mechanical properties, PMP is often compounded with additives and comonomers.

Applications include release films, lightweight structural parts,

hollow fibers, autoclavable medical and laboratory equipment. It is

also FDA compliant and used in many food and beverage applications

like heat resistant and BPA-free tableware, food wraps, baking

cartons and bottles (Nalgene®).