Polyimides (PI)

Properties and Applications

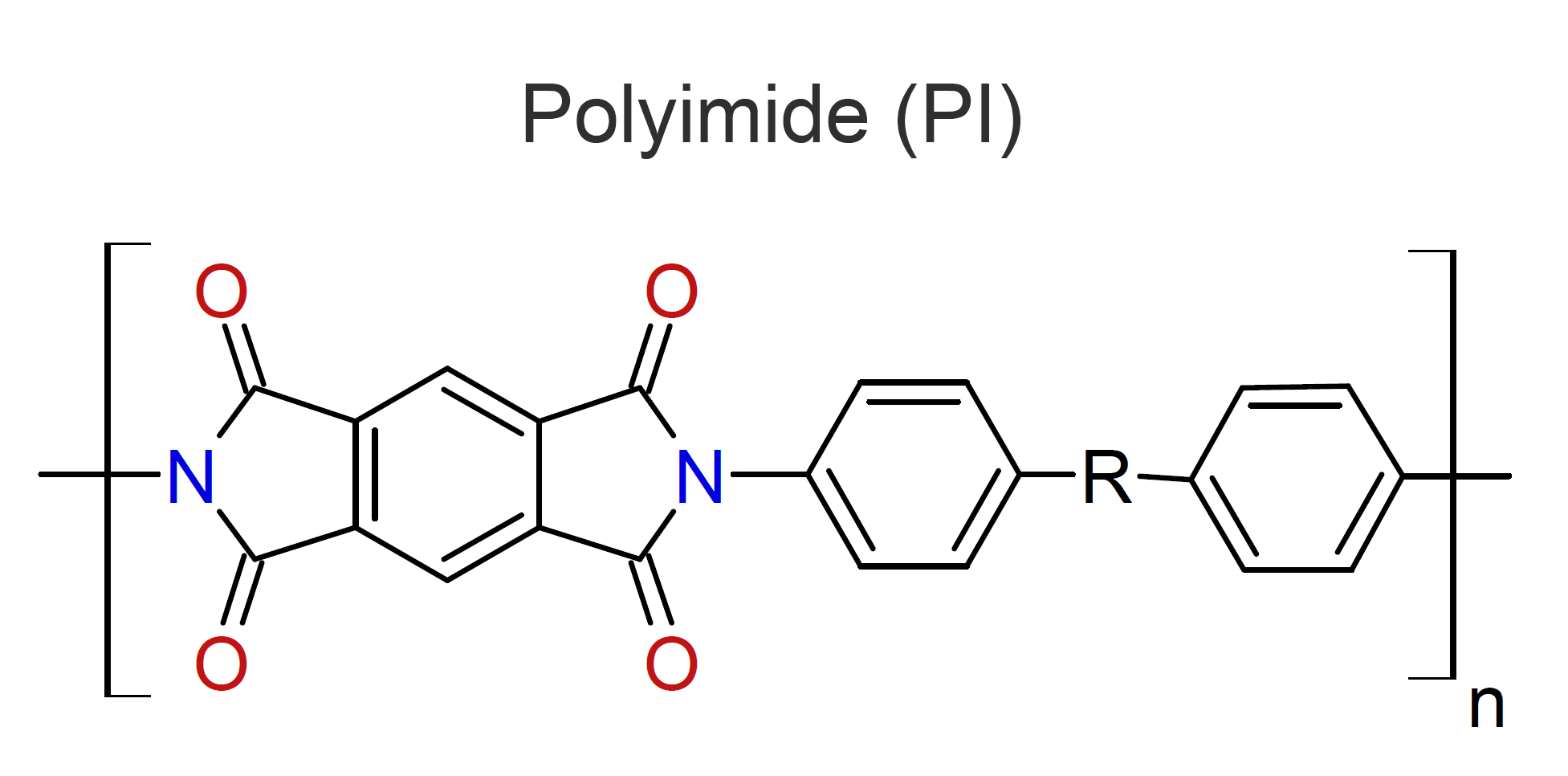

Polyimides (PI) are high performance engineering resins of amber to transparent color that compete with polyketones, polyarylates, and polysulfones in many engineering applications. They are prepared by condensation polymerization of aromatic primary diamines and aromatic tetracarboxylic dianhydrides. The aromatic ring structure along the polymer backbone results in outstanding thermal, mechanical, and chemical properties. The high performance properties are maintained even when exposed to high temperatures.1 However, polyimides have some limitations and shortcomings. For example, they are very expensive and require high processing temperatures and cannot be used above their glass transition temperature unless post annealed.

Polyimides are available both as thermoset and thermoplastic resins. Some of these resins can be processed by injection molding and extrusion. However, the highest performing grades must be processed in precursor form because they will decompose before their melting or softening point is reached. Polyimides are also available as films and common stock shapes.

PIs are often an excellent choice for very demanding applications where very high mechanical strength in combination with high temperature, corrosion, and wear resistance are required. Typical applications include bushings, bearings, sockets and other structural parts that have to survive in harsh and corrosive environments. PIs are also used in high-temperature resistant adhesives, thermally conductive films (Kapton®), filter material for hot gases in the chemical industry, and as fibers for heat protective clothing. In some applications, PIs can replace metals, ceramics and other high performance materials.

Manufacturers & Distributors

Companies |

Brands |