Polycaprolactone (PCL)

Properties and Applications

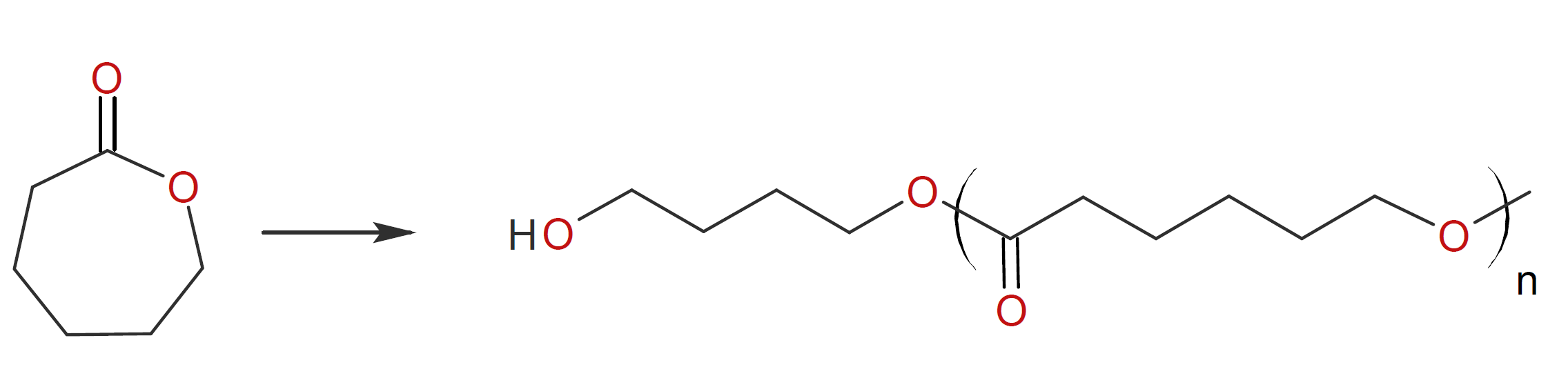

Polycaprolactone (PCL) is a biodegradable, semi-crystalline thermoplastic polyester produced by cationic or anionic ring-opening polymerization of ε-caprolactone at elevated temperatures (≤ 200°C) and in the presence of a suitable catalyst such as dibutyltin dilaurate.1 Initiators are typically diols such as ethylene glycol or 1,4-butandiol which leads to hydroxyl terminated polymers or oligomers known as "polydiols".

High MW PCL has a melting point of about 60°C and, thus, is rather soft at room temperature. In fact, it is one of the softest aliphatic polyesters with an extraordinary high strain at break.

PCLs are commercially available in a variety of molecular weights. The low MW grades are either viscous liquids or hard waxes whereas the high MW grades are soft and flexible polymers with low melting point and low glass transition temperature. This type of polymer has little to no color and is miscible with a variety of polymers.

PCL is mainly used as an additive for resins to improve their processing properties and end use properties such as toughness, flexibility, compression set, and tear strength. The most important use of polycaprolactone (polyols) is in the manufacture of polyurethanes. It imparts good oil, fuel and solvent resistance as well as excellent (low temperature) flexibiltiy and toughness. Like many other aliphatic polyesters, PCL is compatible with a number of thermoplastics. For example it can be added as a polymeric plasticizer to PVC to impart flexibility. Due to its very low softening point, it also finds uses as a remoldable plastic. It softens to a putty-like consistency at about 60°C and can be easily shaped which makes it useful for modeling and as a feedstock for rapid prototyping (3D printing).

Manufacturers & Distributors

Companies |

Brands |