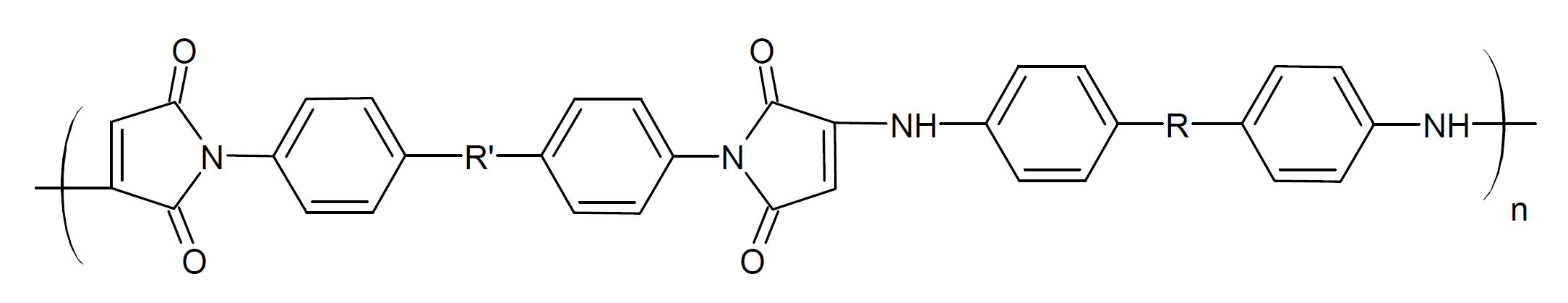

Polybismaleimides (BMI)

Properties and Applications

Polybismaleimides (BMI) are an important class of high-performance thermosetting polyimides that cure by addition rather than by condensation reaction. Their popularity is based on their ease of use, good processability and nonvolatility (no release of gaseous byproducts during processing and crosslinking). Their characteristics are similar to those of polyimides including high strength and rigidity at elevated temperatures; long-term heat and oxidative stability; excellent electrical properties; and relatively low propensity for moisture absorption. They also possess outstanding dimensional stability and provide one of the best high temperature performance. Their heat resistance is usually better than high-performance epoxies but not as good as condensation-cured polyimides.

Bismaleimide resins are known for their high-strength and excellent long-term creep resistance and can replace metal and other materials in many structural applications. They are widely used as matrix resins for high-performance fiber-reinforced plastics (FRP) in electronic and aerospace industries. They also find applications as high performance adhesives. Typically, these reactive resins require high curing temperatures of more than 150 °C and long curing times as well as a postcure at 220 - 260°C for high-temperature applications.

Manufacturers & Distributors

Companies |

Brands |