Polyamideimides (PAI)

Properties and Applications

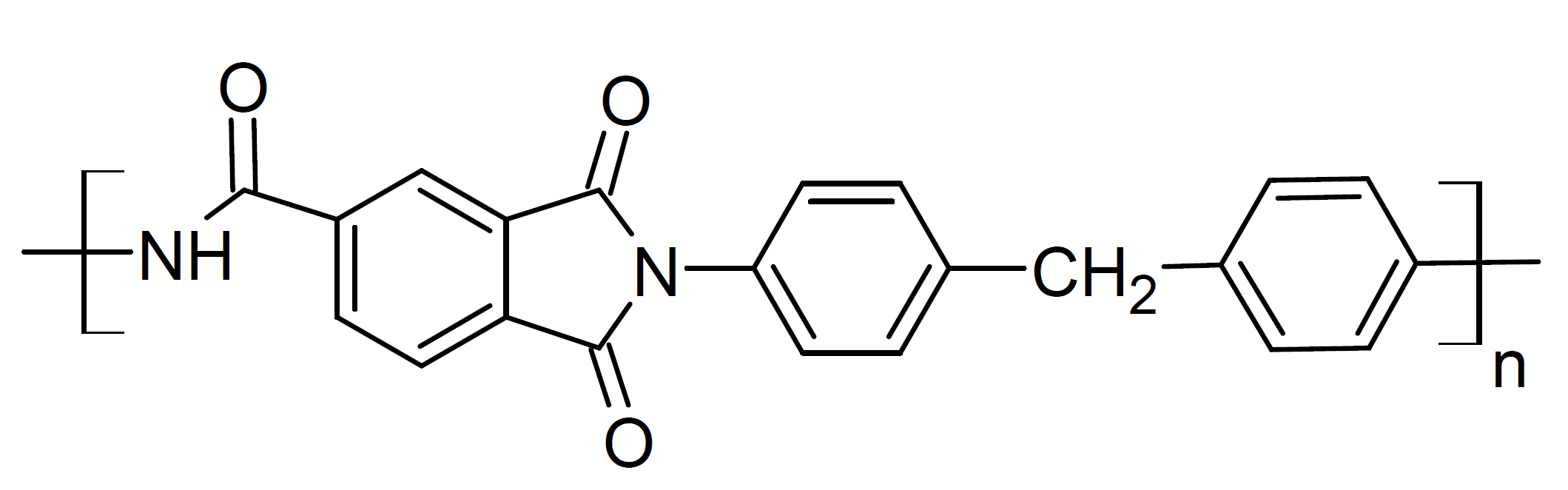

Polyamide-imides (PAI) are high-performing, melt-processable, amorphous thermoplastic or thermosetting resins. They are either prepared from an aromatic diamine and aromatic acid chloride anhydride (acid chloride route) or from an aromatic diisocyanate and anhydride (diisocyante route). A common PAI is the condensation product of trimellitic anhydride chloride (or trimellitic trichloride) and methylenedianiline. Its general structure is shown below:

A large variety of polyamideimides can be prepared from a large number of monomers via these two routes. Even subtle variations in the structure of the dianhydride and diamine can have a significant effect on the properties of the final polyamideimide. Chain stiffness and chain-chain interactions are undoubtedly the most important factors. Both depend on the ratio and arrangement of flexible and rigid groups and on the presence of bulky side groups.

PAI is known for its exceptional mechanical performance and outstanding thermal, and chemical resistance. Some grades maintain their strength and stiffness up to 500°F (260°C) and can be operated in harsh thermal and chemical environments even under severe stress with little to no creep, wear, and chemical degradation.

Typical applications include molded or machined parts for demanding applications including non-lubricating bearings, seals, bushings, pistons, gears, and thrust washers used in jet engines, internal combustion engines as well as electrical and electronic parts. PEI is also widely used in magnet wire enamels for heavy duty motors and in high-performance, non-stick, and corrosion resistant coatings for various other demanding industrial uses.

Manufacturers & Distributors

Companies |

Brands |