Polyarylates (Aromatic Polyesters)

Properties and Applications

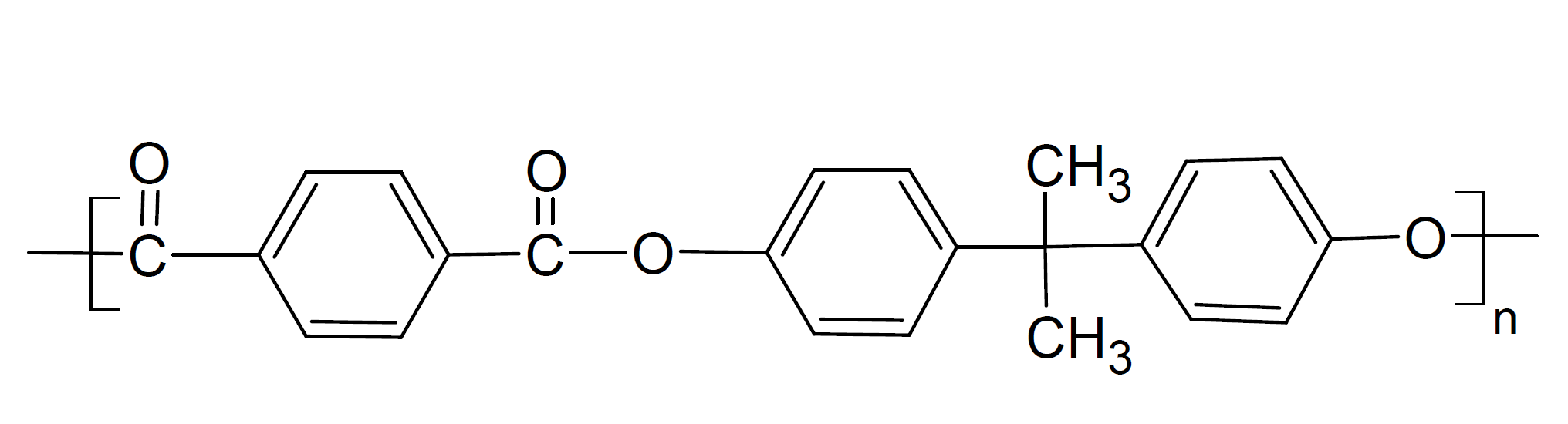

Polyarylates (PAR) are a family of thermoplastic aromatic polyesters. They are often produced by polycondensation of dicarboxylic acids or their diacid chloride derivatives with phenolic compounds. The dicarboxylic acid is usually terephthalic or isophthalic acids and the phenolic compound is Bisphenol A or a derivate of it. The most common polyarylate is poly(bisphenol A terephthalate). The chemical structure of this polymer is given below.

It has one of the highest-levels of heat resistance among transparent resins and will retain its properties for an extended period of time even at relative high strain. Because UV irradiation increases the UV-blocking property of polyarylates, they exhibit excellent weathering properties without addition of any stabilizers; although some yellowing occurs, there is hardly any change in physical properties. Arylates have a transparency as high as PC, transmitting almost 90% light but have better retention of gloss and light transmission after (accelerated) aging than polycarbonate.

Polyarylates are used in a variety of applications including automobiles, precision and medical devices, electronic displays and other electrical parts. Due to their excellent resistance to UV and chemical degradation they find uses in many demanding applications like solar-energy panels, self-lubricating bearings, O-ring seals and pump vanes, especially in demanding environments. Some other arylates are produced as fibers. Due to their high strength and durability, they are often used as reinforcing fibers for ropes, cables, and advanced composite materials.

Manufacturers & Distributors

Companies |

Brands |