Polyacetals (POM)

Properties

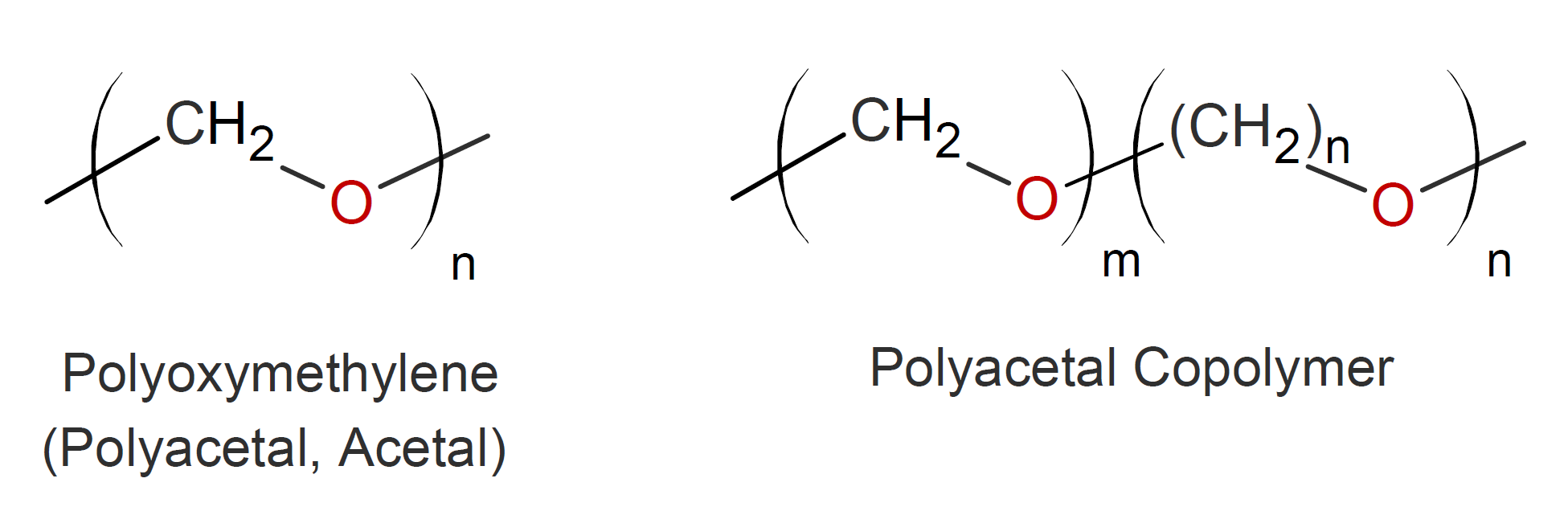

Polyacetals or short acetals are important high-performance thermoplastics. The two most common grades are the homopolymer polyoxymethlyene (also called polyformaldehyde and abbreviated POM-H) and its copolymers with cyclic ethers (POM-C). These resins can be produced by cationic ring-opening polymerization of trioxane (the cyclic trimer of formaldehyde) with or without a small amount of cyclic ether (typically 2- 8 weight percent of ethylene oxide or 1,3-dioxolane).1,2

Acetals are highly crystalline polymers that are known for their high mechanical strength, stiffness, hardness and low coefficient of friction. They also have good heat, fatigue and chemical resistance and are easy to machine. POM-H has a higher level of crystallinity than POM-C. For this reason, it has somewhat better mechanical properties including slightly higher tensile, yield and impact strength and higher heat distortion temperature whereas the copolymers POM-C have greater dimensional stability, lower coefficient of friction and are more resistant to hot water and weak bases.

Applications

POM and its copolymers are widely used as engineering plastics across almost every industry. They are often an excellent choice for applications that require low friction, high impact resistance, high stiffness, and tight tolerances. Examples are machinery parts such as gears, bearings, rollers, and conveyor chains; parts in the transportation industry such as fuel pump housings, cooling-fan parts, fuel caps, door handles, and steering column - gear shift assemblies. Acetals are also widely used in home appliances and tools including food mixers, espresso and coffee-making machines, shower heads, furniture joints and drawer runners, knife and tool handles, and water sprinklers (nozzles).