Ethylene Acrylic Ester Terpolymers

(Acrylate-Maleic Anhydride Terpolymers, AMA)

Properties and Applications

Ethylene acrylic ester terpolymers are random copolymers of ethylene, acrylic ester and a third monomer produced by a high-pressure autoclave process.1 The third monomer is a reactive monomer such as maleic anhydride (MAH) and glycidyl methacrylate (GMA). These copolymers are compatible with many polymer resins and additives including polyamides, polyesters, LDPE, tackifying resins and waxes and possess sufficient thermal stability and fluidity to be blended and processed by extrusion.

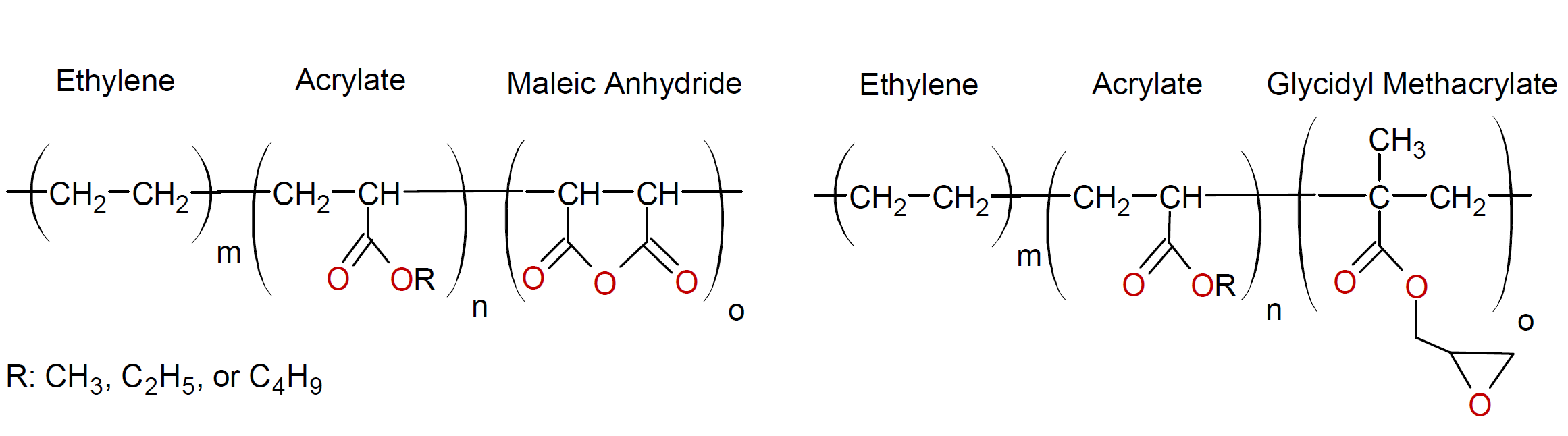

The by far most important ethylene acrylic ester terpolymers are ethylene-acrylic ester-maleic anhydride and ethylene-acrylic ester-glycidyl methacrylate which are sold under the tradename Lotader by Arkema and are shown below.

Due to the presence of glycidyl methacrylate (GMA) or maleic anhydride (MAH), the two terpolymers can form chemical bonds with other resins having amine (-NH2) or hydroxyl groups (-OH) such as ethylene-vinyl alcohol (EVOH). The reactivity also improves dispersion during melt mixing with engineering thermoplastics such as polyamides (PA6, PA66, & PA12).

Ethylene acrylic ester terpolymers are frequently used as tie-layer or adhesive resins in laminates and multilayer film products for the packaging industry. They are also used in pipeline coatings, cables and hotmelt adhesives. They provide excellent adhesion to many substrates like aluminum foils, metallized plastics, paper, board, PE and several other plastics. They can also function as a compatibilizer for polyamides / polyolefins blends or as impact modifiers in engineering polymers such as polyamides and polyesters.

Manufacturers |

Brand Names |