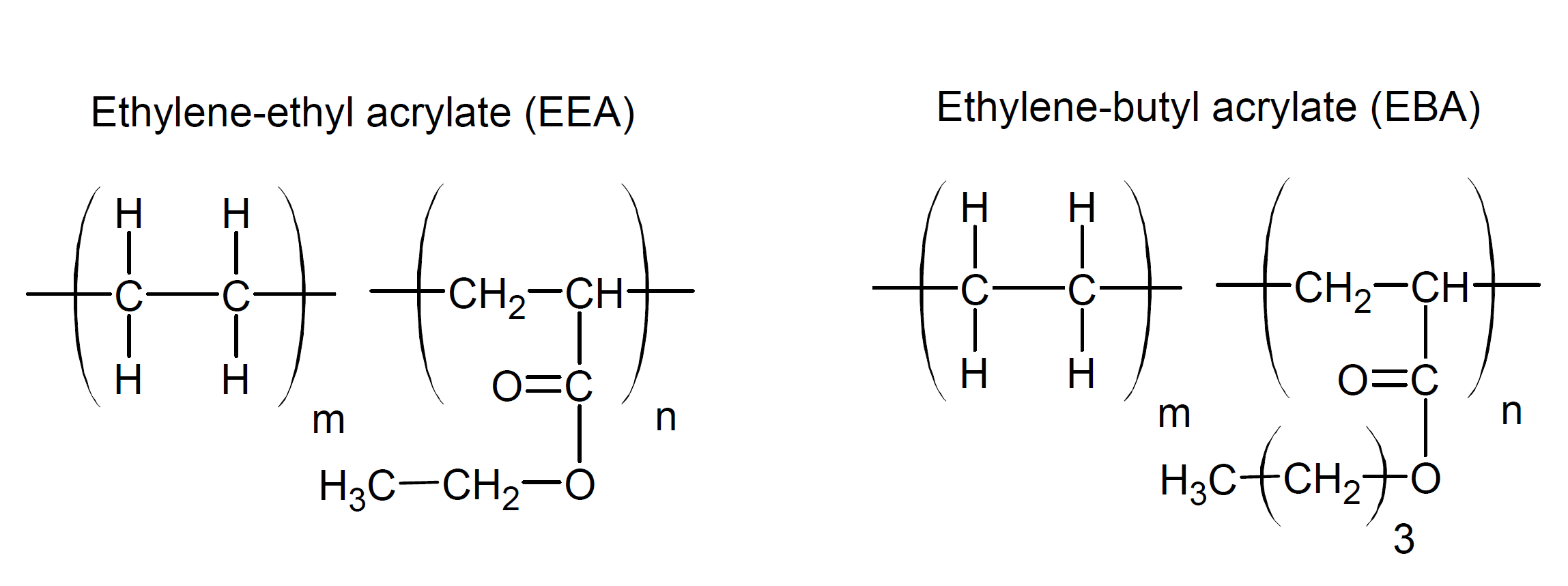

Acrylic Copolymers (AC)

(Ethylene-Ethyl Acrylate & Ethylene-Butyl Acrylate)

Properties and Applications

Acrylic copolymers (AC) are transparent thermoplastic copolymers of ethylene and acrylate with exceptional low-temperature flexibility and impact resistance. The two most important copolymers are ethylene-ethyl acrylate (EEA) and ethylene-butyl acrylate (EBA). They are produced by a high-pressure free radical polymerization. Since the reactivity of the acrylate is much higher than that of ethylene, more acrylate monomers are incorporated at the beginning of the polymerization than towards the end. The resulting heterogeneous molecular architecture provides both good adhesion to polar and non-polar substrates. It also provides good compatibility with a wide variety of polymers. Often small amounts of other monomers such as acrylic acid and maleic anhydride are incorporated in the copolymer which further boost adhesion to polar substrates.

ACs are frequently blended with other thermoplastics such as PP, PE, PA, PET, and PVC to improve their processability and/or to enhance their performance. For example, dispersed ethylene acrylate domains

increase the impact strength of the base polymer by absorbing impact energy. ACs are also known to improve the dispersion of pigments and mineral fillers.

Typical applications of ACs include hot melt adhesives,

co-extruded plastics and foam products, as well as extrusion-laminated sealable layers and films in flexible packaging.