Polynorbornenes (PNR)

Properties

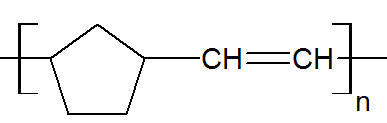

Polynorbornenes or polynorbornylenes (PNRs) are unique commercial elastomers with high glass transition temperatures (> 310K)1, outstanding thermal stability, excellent optical transparency, high friction coefficient, and low dielectric constant. They are produced via ring opening polymerization of norbornene.

Since the unsaturation of the monomer is retained in the polymer, conventional sulfur curing systems can be employed. A common vulcanization system is sulfur and N-cyclohexyl-2-benzothiazole sulfenamide (CBS).

Pure polynorbornene is not an elastomer; to obtain elastomeric properties, the glass transition temperature of the polymer has to be lowered below room temperature. This can be achieved by blending the polymer with common aromatic and paraffinic oils that act as plasticizers. Due to its excellent compatibility with mineral oil and other aliphatic compounds, Tg’s as low as -60°C can be achieved.

PNR elastomers have good heat, ozone, and weathering resistance. They also have excellent noise and vibration damping properties but only fair compression set and poor resistance to swelling in most hydrocarbon oils and low abrasion resistance.

COMMERCIAL PNR Elastomers

The main manufacturer of PNR elastomers is Startech Advance Materials GmbH. The polymer is sold under the tradename Norsorex®.

Applications

PNR is known as a super absorbent polymer for oil. It can absorb up to 30 times of its own weight of oil (average is about 10 times). It is one of the most absorbing oil binding systems for hydrocarbon oils used in the industry.

PNR elastomers are used for the production of a wide variety of rubber articles with very good noise and vibration damping properties and friction control. The polymer can be blended with many other elastomers such as EPDM, NR, NBR, IR, etc.

PNR elastomers find applications in the automobile, electronic, construction and sports-recreation equipment industry. Major products include shoe parts such as mid-sole constructions for sport and work shoes, climbing soles, slip resistant out-soles; dampers for washing and drying machines; sealing for electronic systems; and automotive parts such as bumpers, door sealing, and transmission belts.

The typical working temperature range is -40°C to +70°C (-40°F to +160°F).

1B.G. Shin et al. Macromolecular Research, Vol. 15, No. 2, pp 185-190 (2007): Tg = 330°C and US Patent 6492026: Tg = 320°C