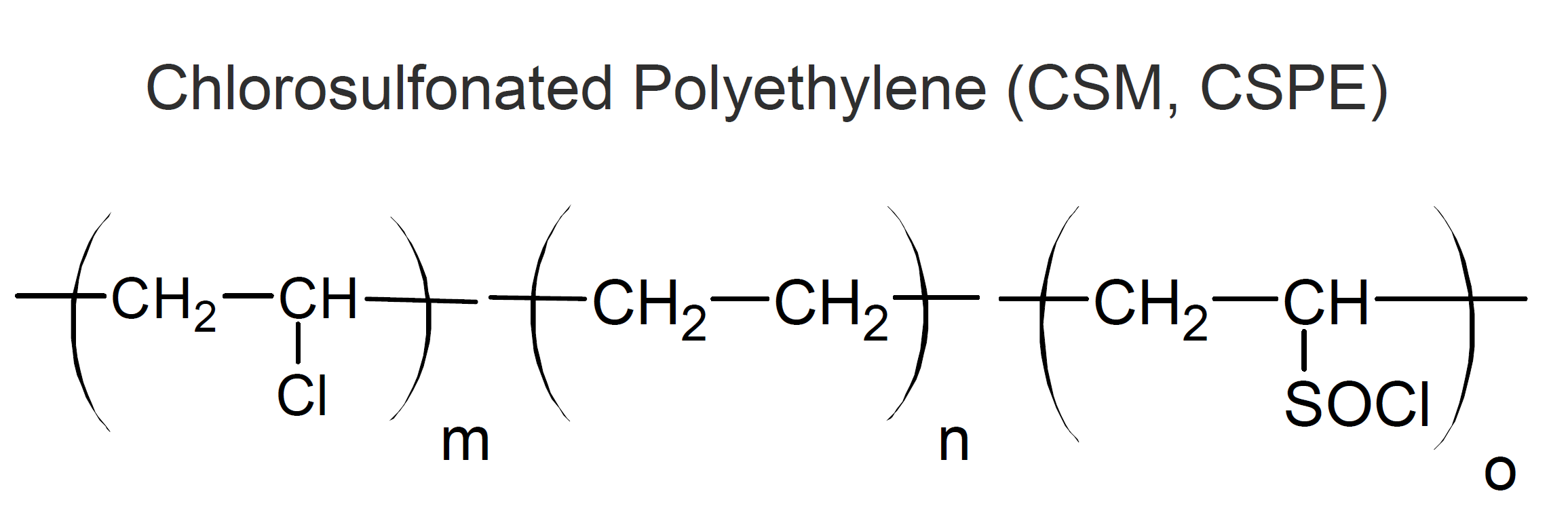

CSM – Chlorosulfonated Polyethylene

Properties

Chlorosulfonated polyethylene (CSM, CSPE) is widely known as Hypalon®.1 It can be considered a superior type of chloroprene, having better heat and chemical resistance.

CSM grades usually contain 20 - 45 percent chlorine which provides excellent resistance to ozone, UV, weathering, and chemicals. This includes oxidizing agents, hot water (when cured) and corrosive chemicals. It also has good resistance to dry heat up to 150°C, low flammability, low gas permeability, and good electrical properties. However, it has poor/fair fuel resistance and its low temperature properties are generally limited, depending on the chlorine content of the CSM grade. Furthermore, its compression set is rather low.

A major advantage of CSM rubber is fast cross-linking (vulcanization) with compounds such as multifunctional amines and peroxides. It can also be crosslinked with sulfur and thiuram accelerators at the sulfonyl groups. However, this type of vulcanization proceeds at a slower rate and the physical properties are typical inferior when compared to peroxide cured rubber.

COMMERCIAL CSM Elastomers

Two important manufacturers and suppliers of chlorosulfonated polyethylene elastomers are Tosoh and Lianda.2

Applications

CSM elastomers are generally useful in electrical applications and as protective coatings against corrosive environments. Its excellent UV stability makes it also useful as a material for outdoor applications Typical applications include acid resistant tank linings, pond liners, static seals, roof sheeting, membranes, fabrics, hoses and electrical cable jacketing.

The typical working temperature range is between -20°C and +125°C.

Notes

-

Hypalon® is a registered trademark of DuPont Performance Elastomers.

In April 2010, the world's largest chlorosulfonated polyethylene elastomer producer, DuPont Performance Elastomers, ceased production of Hypalon. This move created a major shortage in the world's chlorosulfonated polyethylene elastomer market and for end users of CSM. Japan and China are now the largest suppliers of CSM elastomers, with Japan being the largest exporter.