Encyclopedia of Adhesive Technology

A

Abrasion is the removal of material by wearing, grinding, or rubbing the surface of a substrate with hard particles or hard protuberances. In general, abrading an adherend leads to a stronger and more durable adhesive joint because it removes surface contaminations and weak boundary layers. Abrading a surface also creates a larger bonding area and leads to mechanical interlocking. In general, the method of surface preparation must be tailored to the adhesive, adherend and application.

Acrylic adhesives, also called methacrylic adhesives, are one of the most popular structural adhesives. They are often called reactive acrylics to separate them from other acrylic resins that are normally used in pressure sensitive applications. They are thin liquids that polymerize to form tough bonds. They contain similar monomers as anaerobic adhesive; however, they have been carefully formulated to cure even in the presence of air (oxygen). Acrylics often bond through thin layers of oil due to their great solvent power.

Adherend is a body (substrate) that is attached to another by an adhesive. Both the chemical (surface) composition and the mechanical properties of the adherend affect the strength of an adhesive joint. For example, a thick and stiff adherend reduces peel and shear stress and produces a more uniform stress and strain distribution, which, in turn, increases the strength of the adhesive joint.

Adhesive, also known as glue or cement, is any substance that sticks or bonds to surfaces and allows parts to be joined permanently or temporarily. Some types of adhesives can carry significant loads and can replace mechanical fasteners such as rivets, screws, and welds, or they can be used in combination with them.

Adhesive joint is the region at which two adherends are bonded with a (thin) layer of adhesive. The strength of an adhesive joint depends on the type of adhesive and adherend as well as on surface preparation such as solvent wipe, plasma treatment, and abrasion. In general, cleaning the adherends leads to a stronger and more durable adhesive joint because it removes surface contaminations.

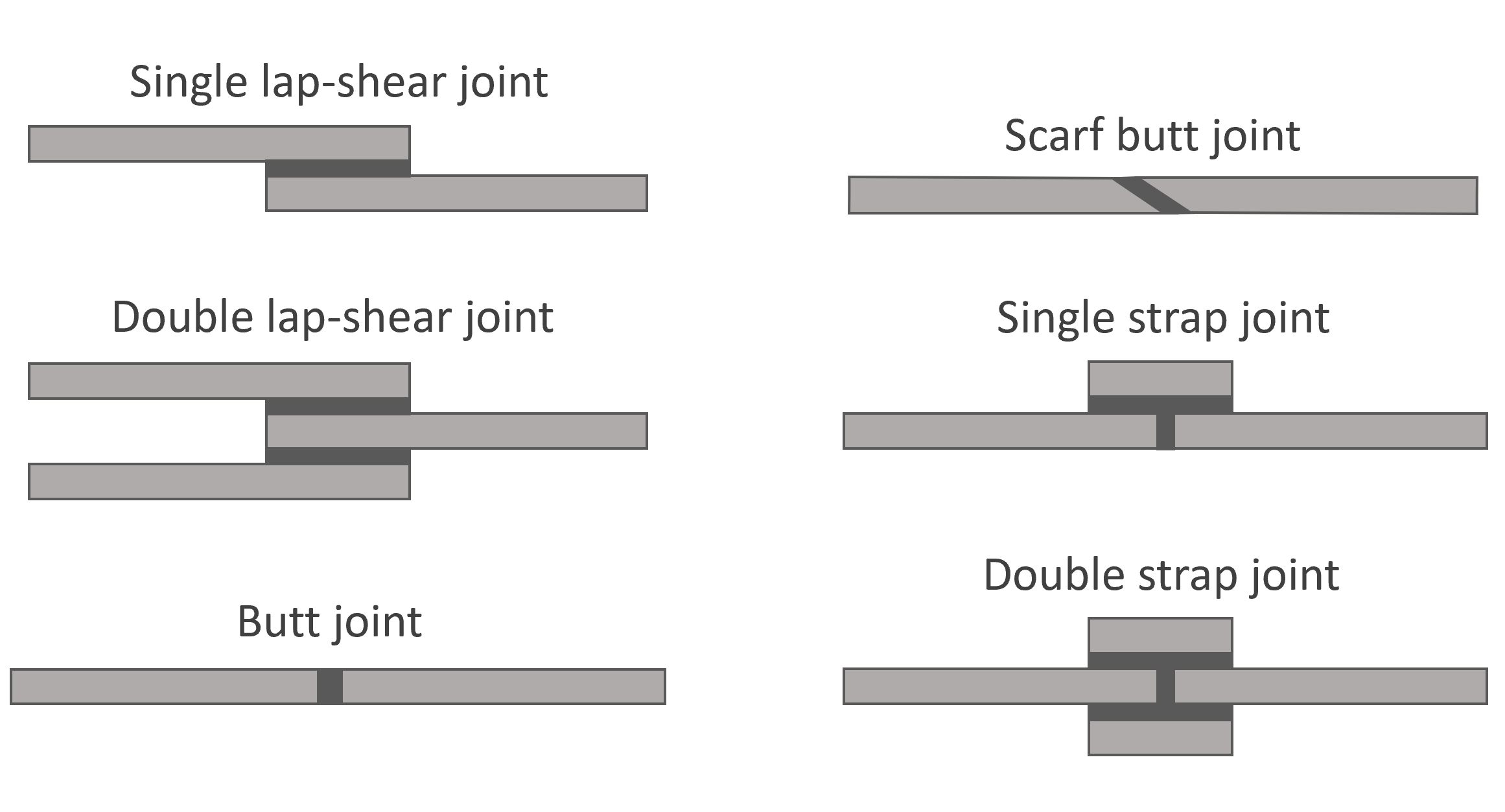

Adhesively bonded joints are widely used in the product assembly industry. Five common flat joint types are single lap-shear, double lap shear, scarf butt, and single and double strap joint. Two common 3D joints are T-joints and corner joints. The type of joint will affect the durability and strength of an adhesive joint. To maximize the strength, excessive peel and tension stress needs to be avoided by choosing a joint design that creates compression and shear rather than peel and tension stress.

Anaerobic Acrylic adhesives are thin liquids consisting mainly of (meth)acrylic monomers that polymerize in the absence of oxygen to form tough bonds when confined between closely fitting (metal) joints. This type of adhesive bonds many common substrates including metals, glass, and ceramics. However, many anerobic adhesives and sealants will cure only when exposed to metal ions, typically coming from a metal surface. They are mainly used to augment the seal of threads or joints and/or to provide a holding force for mechanically joined assemblies.

A-stage is the early stage in the reaction of a thermosetting resin in which the material is still liquid to be dissolved in suitable solvents or diluents and in which the material is reactive enough to be cured.

Autoclave is a chamber that provides controlled temperature and pressure conditions. These machines are frequently used to cure certain types of adhesives in joints and binder resins in composites.